POLYMER CANDLE FILTERS

Online Ordering Support

Hotline

02473068008

Hotline

02473068008

For High-Temperature, High Pressure Polymer Processing Applications

.

.

Features & Benefits

Laser-marked end fittings

Each element is permanently laser-marked for ease of identification and traceability.

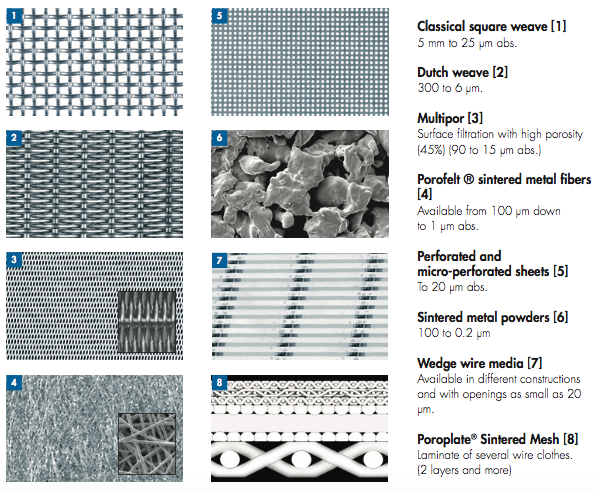

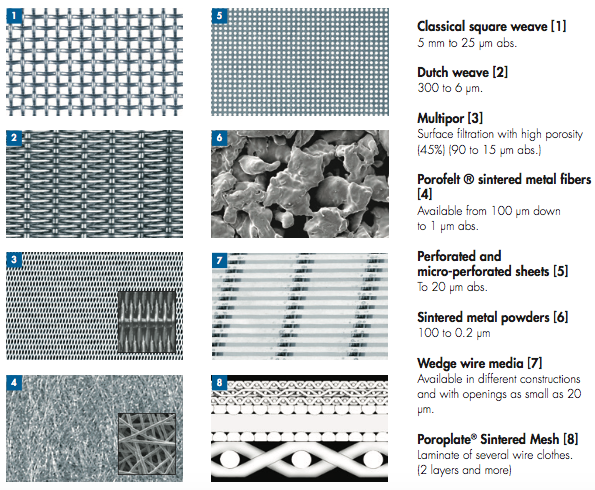

304L/316L stainless steel media

All elements are made from 304L or 316L stainless steel filter media. They are ideal for repeated cleaning cycle temperatures up to 850° F and highly corrosive applications.

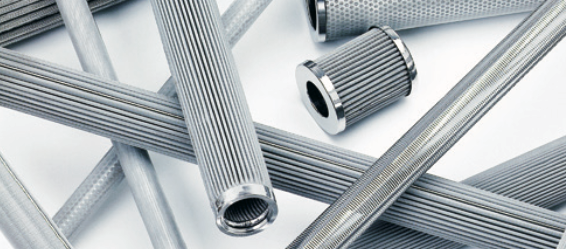

Extended filtration area

Computer modeling optimizes the number of pleats and pleat height to maximize the filtering surface area. In fact, pleated elements have over 3-4x the filtering area as cylindrical elements. This means lower differential pressures, greater dirt-holding capacity and longer on-stream life.

Quality control

Every polymer filter element is bubble-point and air flow tested prior to shipment to ensure product integrity and performance.

Applications

- Synthetic fiber (PET, PA, PP, carbon & more)

- Film (PP, PET, PC, PS, PVBH, PE, & more)

- Non-woven (PP, PE, & more)

- PET bottle

- Engineered polymers

- Rubbers and silicones

...