AIR FILTRATION

FILTER BAG SYSTEM

BHA® Preveil® ePTFE Membrane Laminated Filter Bags

High Efficiency Filtration For Dust Collector

BHA Preveil is made from PTFE resin, a substance with inherent non-stick properties that can be used to help your dust collector operate at maximum efficiency by providing:

• 99.99% efficiency

• Higher airflow

• Better cleaning

• Optimum emissions control

Media. Size. Construction. A lot of careful consideration goes into choosing the ideal filter for your dust collector. That’s where we come in. Our global team of industry specialists has decades of experience in the application of ePTFE membrane filter bags across a wide variety of industries. We’ll help you evaluate your options and select the right filtration solution that can help you improve operations and optimize baghouse performance.

It’s not just the quality of the membranes we make that sets us apart—it’s what we do to them. Using our core competencies in membrane extrusion, lamination and finishing treatments, we design BHA Preveil membrane filter bags to improve filtration efficiency and operate at consistently low

differential pressures. This helps reduce filter changeouts and energy costs, extends filter service life, and can help lower particulate emissions across a wide range of applications.

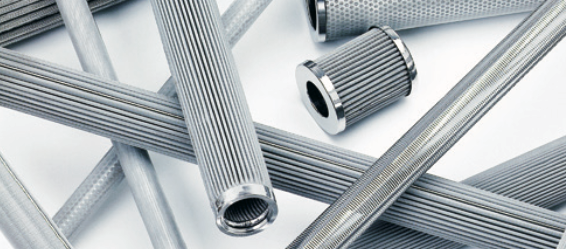

CARTRIDGE FILTER SYSTEM

Innovative Pleated Filter Elements Offering Proven High Performance And Durability

Whether used in new systems or serving as retrofits to existing dust collection equipment, these innovative pleated filter elements prove to be a versatile and cost-effective solution.

Our pleated filter elements deliver valuable benefits:

• Provide superior filtration efficiency

• Promote better airflow for increased throughput

• Reduce air-to-cloth ratios

• Reduce operating differential pressure

• Reduce compressed air consumption

• Eliminate the need for cages

• Are easily installed and removed

Best of all, installation typically requires no modification to existing equipment. You can enjoy improved performance and energy savings without the expense of costly modifications.

Spunbond Media

The media is manufactured by the layering and calendering of fine denier fibers, it features a tight pore structure that better resists particulate penetration. Physically rigid, it can hold a pleat without the support of backing material and withstand temperatures up to 265° F (130° C). Spunbond media, when pleated and molded into the filter, can increase filtration surface area 3 to 4 times more than conventional filter bags. This can lead to a dramatic increase in filtration efficiency while operating at a significantly lower differential pressure.

DUST COLLECTOR

Most Versatile And Economical Solution For Capturing Dust And Dry Pollutants

|

|

Standard Features |

A Wide Range Of Applications

| • Metalworking • Buffing • Grinding • Polishing • Blending • Filling • Material Handling |

• Packaging • Screening • Weighing • Finishing • Sanding • Sawing • And more |

LIQUID - CHEMICAL FILTRATION

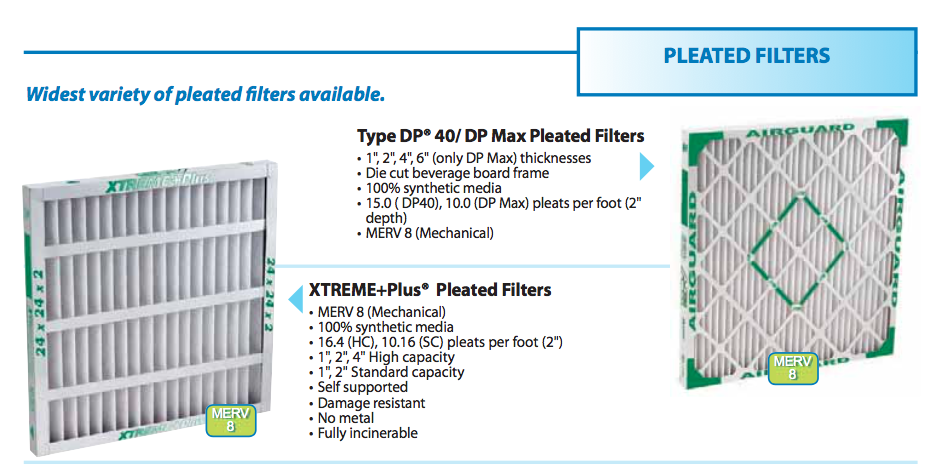

PLEATED FILTER

Multipoly Filter Cartridges - Multi- layer Polypropylene Media. Pre-filter

Cobetter MutiPoly Filter Cartridges is an all-polypropylene pleated depth filter cartridges. The design adopts depth filter technology for a graded pore size, higher dirt holding capacity, avoids filter surface jams, and eliminate ink contaminants (gels and agglomerates). The graded pore size distribution from coarse (upstream) to fine (downstream) removes particles gradually and extends the filter's service life.

Features and Benefits

- Media constructed of 5-7 layers with a larger pore size on the upstream and a smaller pore size on the downstream. This enables additional particle loading and higher dirt holding capacity.

- Multi-layer Nano Fiber Media eliminates particles according to pore size distribution and sighnificantly increases lifetime.

- Multi-layer Nano Fiber Media provides excellent removal of contaminants capabilities including gels and agglomerates.

- Popypropylene construction yields excellent compatibility wih most ink chemistries.

MBC MELT BLOWN FILTER

Cobetter Melt Blown Filter Cartridges

Cobetter melt blown filter cartridges are made of polypropylene non-woven with no surfactants, binders, or adhesives. These fiters have long service life and high dirt holding capacity. They are suitable for the water treatment industry.

Features And Benefits

- 100% pure polypropylene depth filter with high dirt holding capacity .

- No wetting agents, solvents, surfactants, or binders, or adhesives .

- Reduce filtration cost

- No fiber-releasing

Typical Applications

- Water Treatment

- Potable Water Filtration

- Cooling Water Systems

MBCY MELT-BLOWN FILTER

Cobetter Meltgradient High Efficiency Depth Filter

Meltgradient series are the PP melt-blown cartridge with the absolute filtration rate. It adopts the reasonable gradient pores configuration, cooperating with the structure of "deep". The cartridge is capable of efficiently capturing particles of different sizes, and its flow rate and life are not inferior to the pleated cartridge. Polypropylene raw material that meets FDA requirements, with extensive chemical compatibility, suitable for filtering inks, coatings, sovents, deionized water,etc.

Features and Benefits

- Particle interception efficiency is up to 99.9%. For the structure with gradient pores, the inner layer is interwoven with high density nano-fibers.

- Long service life, high flow rate. Due to the polypropylene fiber with different linear diameters and unique interwoven density control process, Meltgradient TM has a porosity far beyond that of similar products, which means lower pressure loss across the cartridge and higher dirty holding capacity.

- High purity. Using long fiber fusion and spray process, continuous fiber hot melt interweave into rich and stable pore structure. No adhesive or surfactant, no silicone oil, low preciptate.

- Extensive chemical compatibility. Fully polypropylene structure, complete series with reinforced center bar and optional external frame/end cover, the 68MBCY type. The cartridge can withstand the pressure difference of 4Bar and avoid short circuit of material caused by deformation of cartridge core when using .

- Wide range of optional filtration rate. It is available from 0.3μm to 120μm, which meets various operating conditions.

Application

- Printing ink, Inkjet ink, dyestuffs

- Automotive Paints, Hard Coatings

- Monomer, polymers, solvent

- D.I water prefiltration and post filtration, R.O water prefiltration, makeup water

BAG FILTER

Cost Effective EBF Series

EBF economic filter bags are made of high efficiency needle felt, processed by the surface treatments of singeing, calendaring and coating, eliminate the risk of fiber releasing. The seamless thermal bonding technology ensures no side leakage. EBF is available in double layer structure that increases the effective filtration, dirt holding capacity and enhanced retention efficiency. EBF is the cost effective solution for medium-low viscous fluids.

Features and Benefits

- Tight structure and treated surface by singeing, calendaring and coating process, no fiber releasing risk.

- Seamless thermal bonding technology, no side leakage risk.

- Depth filtration media, excellent dirt holding capacity.

- Optional double layer structure provides higher dirt holding capacity and higher retention efficiency than single layer structure.

- Fits the application of medium-low viscous liquids which contains solid or soft particles.

H-SCF/SDF/SEF/SFF FILTER HOUSING

Multi-Round Sanitary Housings. High Flow Sanitary Rate Grade

Multi-Round Sanitary Housing designed for liquid filtration with vary flow rates.

Flow redesign with flow pattern of side-in and bottom-out reduce cost when compared to bottom-in bottom out flow pattern. In addition, top-inlet opening eliminates the need to move the housing body while installing the filter elements, thus reducing filter change-out time.

Strongly recommended for use in life science filtration applications, it meets sanitary requirements and GMP standards. Features include mechanical polishing with a Ra of 0.3μm, easy-to learn, and thorough drainage, which eliminates concerns about remaining liquids. In adddition, the filter housing is available with a detachable plate for thorough cleanng with strict cleaning requirements.

It is also available in an electro-polish finish for filter housings with 12 rounds or less.

Configurations

H-SCF: bottom-opening, fixed plated; bottom-in bottom-out flow pattern

H-SDF: top-opening and bottom-opening; fixed plate; bottom-in bottom-out flow pattern

H-SEF: bottom-opening; detachable plate; bottom-in bottom-out out flow pattern

H-SFF: top-opening and bottom-opening; detachable plate; bottom-in bottom-out out flow pattern.

H-SPF IN-LINE SANITARY FILTER HOUSING

Single-Round, Inline-Style, Easy In Cleaning

H-SPF In-line Sanitary Filter Housing is designed and manufactured according to sanitary-grade requirements and GMP standards. Widely used in life-science applications.

Due to the compact design of the top-in and botto-out flow pattern, we recommend to use the filter housings as vent or pipe conector. H- SPF II Filter Housing is designed for filtration with low volume requirements. Small filter elements with 56mm diameter will fit in this housing.

Features And Benefits

- Quality surface finishing- Interal Ra: 0.3μm; External Ra: 0,4μm. Sanitary design prevents entrapment or build-up of contaminants. All electro- polishing is also available.

- Vent & Drain: Threaded sleeve is separated by a stepped thread so that the connection tube will not wave when in draining or venting operation.

- Enlarged vent and drain - interal diameter connects with an 8mm tube.

- Quick-release closure clamp allows for quick disassembly - our sectional closure clamps increase pressure endurance by 20% compared to normal clamps.

- When running at high operating pressure, quick-release closure clamps provide perfecting sealing for PTFE o-rings. Max. Operating Pressure can reach 10 bar.

- Adjustable nut on the egs allows for filter length to be adjusted.

PROCESS FILTRATION

WELD PACKS

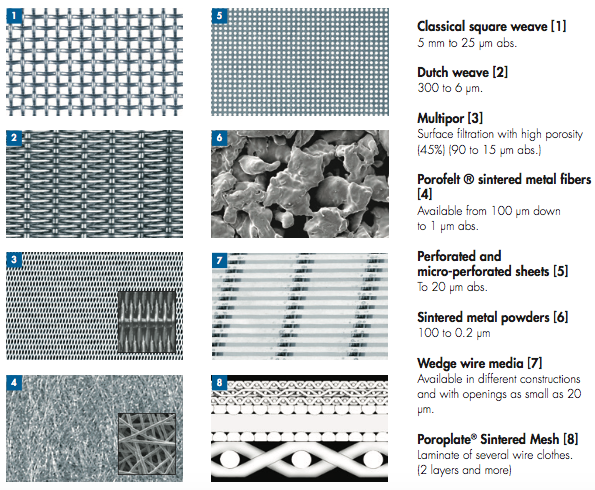

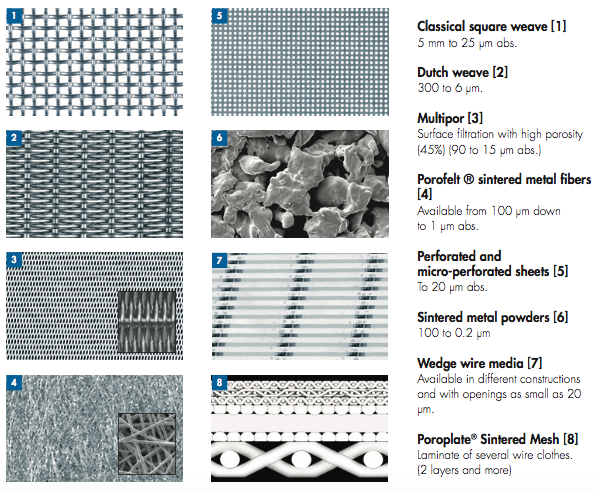

Purolator Multiple Layers of Wire Woven Cloth Spot Welded Together

Weld packs are made from multiple layers of wire woven cloth spot welded together. We offer a wide range of products as well as customized products based on your filter needs. Our large stainless steel wire woven cloth inventory enables us to be the cost leader in providing screen packs.

Why should you choose our Multti-Layer Screen Packs (Weld Packs)?

- Multiple layers of wire woven cloth spot welded together

- Plain steel mesh

- Stainless steel wire woven cloth

- Alloys available: Inconel®, Monel®, Hastelloy®

- Other woven cloths in brass, copper, or galvanized steel

- Wide variety of weaves

- Available ratings range from 2 - 200 microns

- Engineered lay ups to optimize performance to meet required flow rates, pack pressure, and specified filtration levels

SINTERED PACKS

Purolator Sintered Fiber Metal Felt

Sintered fiber metal felt media is available in micron ratings as low as 2.5µ, has a very high porosity, and thus provides a very low-pressure drop. The media can be fabricated into tubular form, or pleated to provide increased filter area. The media can be configured as a depth media, and has a much higher dirt holding capacity than either sintered metal powder or woven wire cloth.

Features

- High strength

- No media migration

- Continuous operating temperature range of -50°C to 550°C (-65°F to 1000°F)

- Stainless steel construction

- Corrosion resistant

- Filtration from 1 micron to 200 micron

- Custom configurations including layers of perforated plate, fiber metal felts and photo-etched foil

- Abrasion resistant

- Easily fabricated into virtually any shape, size or configuration

- Precise pore size distributions and fluid flow permeability

- Dimensionally stable

- Excellent weldability

- Easily cleaned

- Most standard sheets in stock for immediate delivery

Typical Applications

| Filtration | Fluidizing | General |

|

|

|

POLYMER DISC FILTER

High Performance Polymer Filtration

Constructed from sintered wire cloth laminates or sintered non-woven fiber metal felt media, these polymer leaf disc filters are the product of choice for polymer film and specialty polymer producers. The unique design and configuration of the leaf disc assembly maximizes the effective filtration area while minimizing the residence time of the polymer itself, thereby reducing the risk of polymer degradation.

Features & Benefits

Available media and micron ratings

Porofelt® diffusion-bonded fiber metal felt depth media are available from 3µ - 60µ absolute. Poroplate® sintered wire cloth media is available from 10µ- 200µ absolute.

Materials/method of construction

Polymer leaf discs are available in 316L stainless steels and other alloys. These alloys, combined with our advanced construction/welding methods, result in excellent corrosion resistance and a useful life of many cycles.

FRAMED PACKS

Purolator - Multiple Layers of Wire Woven Cloth Encapsulated In An Aluminum Binding

Frame packs are made from multiple layers of wire woven cloth encapsulated in an aluminum binding. We offer a wide range of products as well as customized products based on your filter needs. Our large stainless steel wire woven cloth inventory enables us to be the cost leader in providing screen packs.

In addition to 316L stainless steel, other metals and alloys are available to meet your special requirements, such as greater temperature and corrosion resistance.

Stainless Steel: 316L, 204L, 310L, 347, 430 - Hastelloy C-276, C-22, X, N, B, B2 - Inconel 600, 625, 690 - Nickel 200 and Monel 400 (70Ni - 30Cu) - Titanium - Alloy 20 and many others.

Why choose Purolator Frame Packs?

- Multiple layers of wire woven cloth encapsulated in an aluminum binding

- Plain steel mesh

- Stainless steel wire woven cloth

- Alloys available: Inconel®, Monel®, Hastelloy®

- Other woven cloths in brass, copper, or galvanized steel

- Wide variety of weaves

- Banding material is available in a variety of thicknesses, band widths, and materials (stainless steel)

- Framed packs reduce changeout time due to easier and safer handling, and improved sealing

- Rigid form helps control the flatness of the pack improving sealing and consistency of product

- Sizes are compatible with OEM Screen Changers

- Available ratings range from 2 - 200 microns

POLYMER CANDLE FILTERS

For High-Temperature, High Pressure Polymer Processing Applications

.

.

Features & Benefits

Laser-marked end fittings

Each element is permanently laser-marked for ease of identification and traceability.

304L/316L stainless steel media

All elements are made from 304L or 316L stainless steel filter media. They are ideal for repeated cleaning cycle temperatures up to 850° F and highly corrosive applications.

Extended filtration area

Computer modeling optimizes the number of pleats and pleat height to maximize the filtering surface area. In fact, pleated elements have over 3-4x the filtering area as cylindrical elements. This means lower differential pressures, greater dirt-holding capacity and longer on-stream life.

Quality control

Every polymer filter element is bubble-point and air flow tested prior to shipment to ensure product integrity and performance.

Applications

- Synthetic fiber (PET, PA, PP, carbon & more)

- Film (PP, PET, PC, PS, PVBH, PE, & more)

- Non-woven (PP, PE, & more)

- PET bottle

- Engineered polymers

- Rubbers and silicones

...

OIL PARTICLE DETECTOR

ICOUNT OIL SAMPLER (IOS)

Accurate Condition Monitoring made Quick, Simple and Cost Effective

The icountOS (IOS) is an innovative solution to the challenge of measuring the quality of hydraulic oils and hydrocarbon fuels in many different applications: from renewable energy, marine and offshore, to manufacturing, mobile, agriculture, military and aerospace.

How It Works

The IOS quality condition monitor for hydraulic oils and hydrocarbon fuels uses advanced technology to produce extremely repeatable results.

At the heart of the system is a sophisticated laser detector, using a light obscuration flow cell, providing continuous measurement of fluid flow passing through a sample tube.

Measurements are taken every second as standard, although measurement intervals and test period can be defined by the user, with results being reported immediately and updated in real time. Data is displayed on a built-in OLED digital display and can also be stored for subsequent upload via the embedded icount’s web page interface connecting through an RJ45 cable.

Features

Proven laser detecton technology

High onboard test data storage capacity

Quick connection

Tough storm case

Fast contamination detection

Complies with the latest standards

Long life remote operation

Fluid and pressure control

Pressure reducing valve (prv)

ICOUNT PARTICLE DETECTOR (IPD)

Most Up-To-Date Technology In Solid Particle Contamination Analysis

Parker Hannifn’s Icountpd Represents The Most Up-To-Date Technology In Solid Particle Contamination Analysis. The Icountpd Is A Compact, Permanently-Mounted Laser-Based Particle Detector Module That Provides A Cost-Effective Solution To fluid Management And Contamination Control.

The icountPD has just one setting to control the accuracy, stability and sensitivity of the measurements and that is the ‘Measurement Period’. This can be set from fve seconds to 180 seconds. The longer the Measurement Period, the more contaminant is measured, averaging out any spikes seen on a smaller sample. The shorter the Measurement Period the more sensitive the icountPD is to small slugs of contaminant, but also the performance on clean systems can be reduced. Thus, the user can select how sensitive the icountPD is to spikes of contaminant, and how quickly it responds to contamination levels above the set point (‘limits’)

Overview

• Permanently installed non intrusive

particle detector

• Proven technology in detecting changing

levels of contamination

• Utilizes Light obscuration technique

• Fit and forget system condition monitoring

• 24/7 continuous detecting (Baby-sitter)

• Multi-standard cleanliness reports

ISO4406:1999

NAS1638

Features

•Local display with power and alarm outputs: 0-3, 0-5, 4-20mA or J1939 CANBUS

• M12 or Deutsch Connections

• 9 – 40 Volt power supply

• Up to 500 cSt rating

• Bi Directional flow cell

• IP66 rated

• Onboard Moisture sensor option

• Requires flow rate of 40 – 140 ml/min

• Requires minimum pressure of 2 bar

Benefits

• Cost effective solution to Online Particle Detection

• Easy to read Go – No Go display

• Reduced downtime through predictive maintenance

• Reduced component failure by contaminant control

• Ease of scheduled maintenance

• Awareness of absorbed water contamination (%RH) before saturation occurs